Ergonomic, functional design

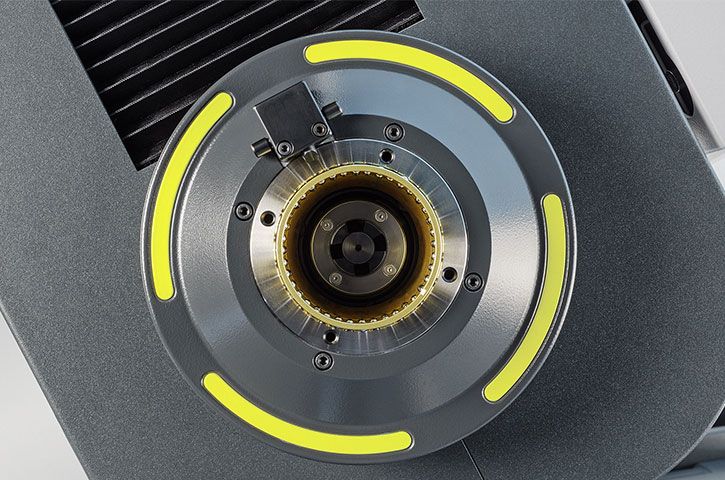

Membrane keypad for power-activated spindle clamping and spindle locking

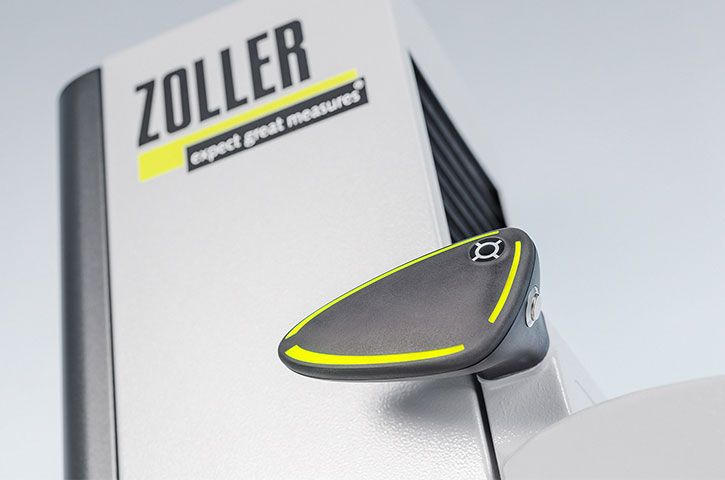

Single-hand operating device »eQ«, with additional function button

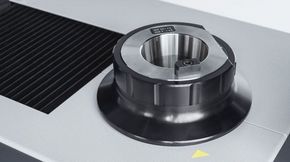

Universal »ace« high-precision spindle

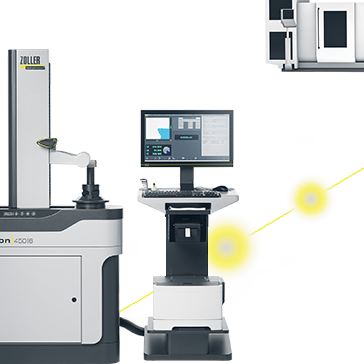

Can be networked with existing production elements

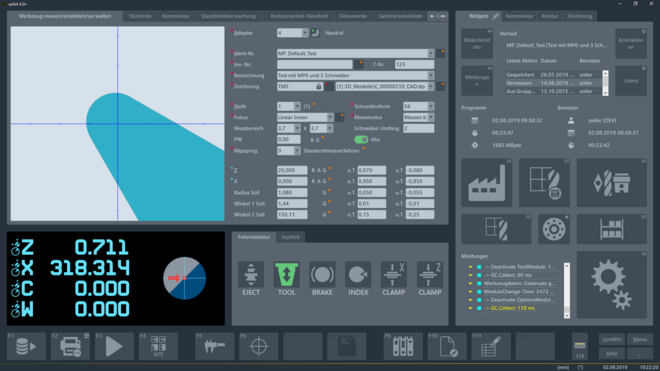

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Measuring range Z | Measuring range X | Max. tool Ø | Snap gage Ø | |

| »venturion 450« | 450 / 620 / 820 mm (17.7 / 24.4 / 32.3 inch) | 210 / 310 mm (8.3 / 12.2 inch) | 420 / 620 mm(16.5 / 24.4 inch) | 100 mm (3.9 inch) |

| »venturion 600« | 600 / 800 / 1.000 mm (23.6 / 31.5 / 39.4 inch) | 300 / 400 mm (11.8 / 15.8 inch) | 600 / 800 mm (23.6 / 31.5 inch) | 200 / 100 mm (7.9 / 3.9 inch) |

| »venturion 800« | 600 / 800 / 1.000 / 1200 / 1400 / 1600 mm (23.6 / 31.5 / 39.4 / 47.2 / 55.2 / 63 inch) | 500 / 600 mm (19.7 / 23.6 inch) | 1000 / 1200 mm (39.4 / 47.2 inch) | 200 / 0 mm (7.9 / 0 inch) |

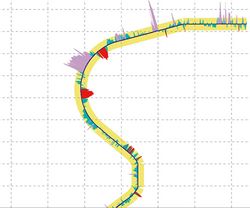

Vertical and Horizontal Dimensions, Radius, and Angle of Standard Cutting Tools

Measuring program for the simple measurement of vertical and horizontal dimensions, radius and angle of standard cutting tools.

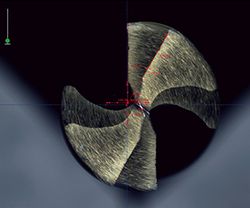

Diameter, Chamfer Lead, Taper, Distance at Single Cutting Edge Reamers

Measuring program for the measurement of single cutting edge reamers with support bar and with the snap gauge method.

Vertical and Horizontal Dimension, Angle, Projection

Measuring program for the measurement of reamers for valve seat machining.

Theoretical Tip

Measuring program for the determination of the theoretical tip at tapered cutting tools over several measuring points.

Tip Angle/Negative Crown

Measuring program for the determination of tip angles with the aid of two points.

Autofocus for »pilot«

Using the CNC controls for the spindle (C axis), the cutting tool edges on multi-insert cutters are also automatically approached and focused. This guarantees user-independent measuring results.

Precise/exact angle measurement

The rotation sensor positions the C axis fully automatically to the target angle. This allows the highly-precise measurement of spiral angles and divisions, as well as wobble compensation.

Center height measuring

A perfectly preset rotation center increases the tool life and thus reduces your tool costs. Simultaneously, you shorten fitting times, prevent rejects and improve the quality of your workpieces.

Tool inspection For axial and radial inspection and testing of the contours of radii, angles, distances and wear and tear in incident light, with 50-times magnification of the cutting tool edge.

»zidCode« with labels With »zidCode«, data is quickly and easily printed onto labels and can be scanned directly into the CNC machine control. This means data transmission without errors.

Automatic tool identification The read/write head is moved fully automatically using CNC axes to the RFID chip on the tool holder clamped in the ZOLLER presetting and measuring machine. The tool data is written automatically by the RFID system to a code carrier on the tool holder and can be read at the processing machine.

Manual fine setting

Hand wheels simplify the fine adjustment of the X and Z axes specifically for tool inspection.

Data output with DNC system prepared in a controller compatible manner

Safe, quick and guaranteed error-free data transfer to your CNC machine

The »venturion« presetting and measuring machine is characterized by unique ergonomics, maximum flexibility and precision. The module design of this presetting and measuring machine gives you the freedom to put together your individual presetting and measuring machine optimally matched to your production processes.

All the basic functions for measuring and presetting your tools are possible with the basic version — you profit from photorealistic input dialogs, automatic cutting edge detection, automatic zero point monitoring and much more. For example, modules can be added for tool inspection, for center height measuring, for measuring reamers or for heat shrinking tools. »venturion« offers every possibility for individual adjustment.

ZOLLER »tribos« is a presetting, measuring and heat shrink machine fitted with the SCHUNK TRIBOS clamping system. As a result, with »tribos« you can preset and measure tools of all kinds, and on the other hand SCHUNK TRIBOS tools can be clamped and unclamped and then measured and preset. The TRIBOS clamping unit is automatically guided on a linear unit to the tool holder and after the end of the clamping/unclamping procedure it is also automatically returned to the starting position. It could not be quicker, more precise or more convenient

Long-lived through consistent use of high-quality brand components

Swiveling clamping unit for measuring and presetting long tools without the TRIBOS system.