Quick and precise recording of different object geometries

Three-dimensional target-actual comparison

CNC-controlled axes that can also be moved manually for random sample measurements.

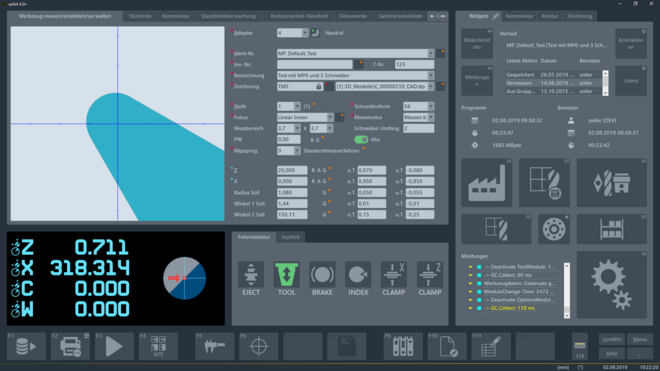

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Max. tool length | Max. tool Ø (with / without swivel mechanism) | Max.snap gauge Ø | Number of axes | Weight | |

| »3dCheck« | 600 mm (23.6 inch) | – / 100 mm (3,94 inch) | 100 mm (3,94 inch) | 5 | 1.400 kg (3 086 lbs) |

»expert« Measuring Program Generator

Global measuring program for the measurement of cutting tools in transmitted and incident light, at the circumference, at the end face and in chip space.

Tool Contour

Measuring program »lasso« for the automatic target-actual-comparison of the target and actual contour of cutting tools.

»3dCheck« captures, digitises and analyses complex tools and is the perfect inspection machine for fast and process-oriented 3D digitisation. This measuring machine combines the advantages of the optical ZOLLER »Z3dCam« (3DSensor) with high-precision CNC axes and fully automatic transmitted light image processing. Especially in the field of reverse engineering, in quality assurance, in R&D up to tool inspection, the use pays off: for example, due to the time-saving real-time image transmission, the comfortable, intuitively operable ZOLLER software interface and the possibility to export the 3D measurement data in a standardised format into the customer's own CAD system for further processing - contact-free without damaging the tools.