Universal

Measure, inspect, record- Universal measuring machine for all cutting tools

Precise

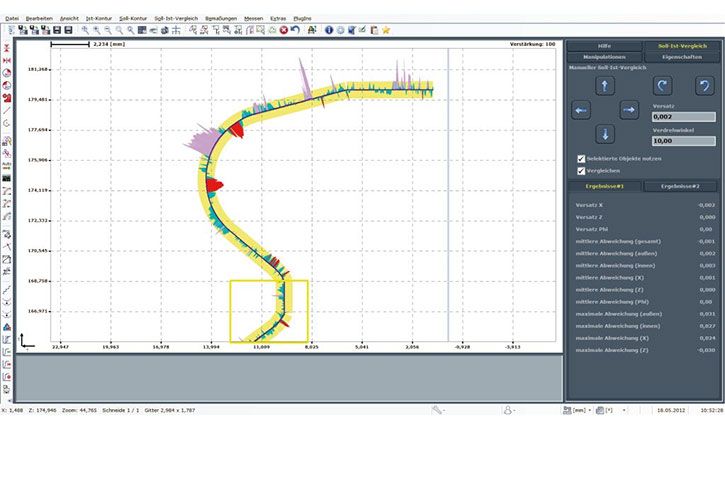

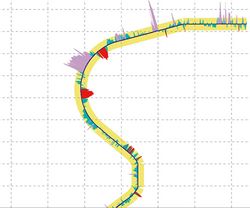

Precisions camera swiveling with incident light image processing and segmented LED illumination for inspecting axial and radial geometries on tools

Extensive

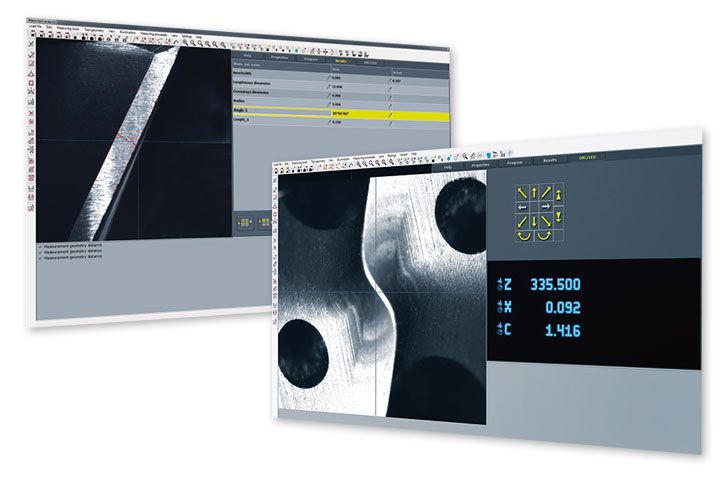

»pilot 3.0« image processing technology with extensive software functions and integrated measuring programs for inspecting and measuring tools

User-independent

Simple and repeatable inspection, measuring and documentation by mouse click

Perfect

Substantial documentation - automatic generation, saving and output of inspection reports

In any position for measuring in the batch of cutting and corner radii.

Precision camera swivel for axial and radial measuring in incident light

Software package: Measuring grinding discs

High-precision evaluations of sectional views in »lasso«.

Incident light measurement with »metis« for any parameters radially on the circumference and axially on the face geometry.

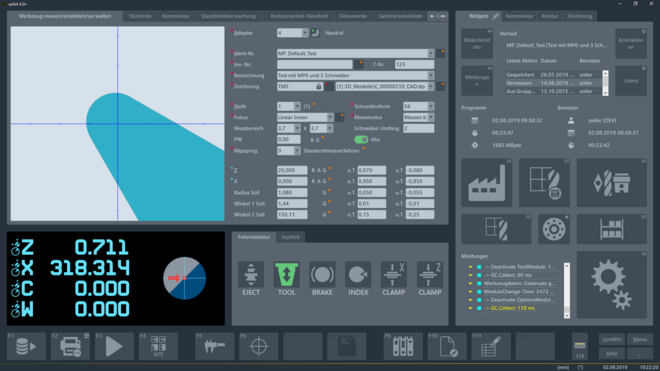

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Measuring range Z | Measuring range X | Ø | Snap gage Ø | |

| »smartCheck 450« | 450/600/800 mm (17.7/23.6/31.5 inch) | 175 mm (6.9 inch) | 350 mm (13.8 inch | 35 mm (1.4 inch) |

| »smartCheck 600« | 600/800/1000 mm (23.6/31.5/39.4 inch) | 175 mm (6.9 inch) | 370 mm (14.6 inch) | 80 mm (3.1 inch) |

| »smartCheck 800« | 600/800/1000/1200 mm (23.6/31.5/39.4/47.2 inch) | 500 mm (19,7 inch) | 900 mm (35.4 inch) | 300 mm (11.8 inch) |

Diameter, Chamfer Lead, Taper, Distance at Single Cutting Edge Reamers

Measuring program for the measurement of single cutting edge reamers with support bar and with the snap gauge method.

Vertical and Horizontal Dimension, Angle, Projection

Measuring program for the measurement of reamers for valve seat machining.

Whether as a manual or 3-axis-CNC version: »smartCheck« is the powerful universal measuring machine for all cutting tools As a result you can check your tools efficiently before and after grinding in order to fulfill DIN EN ISO 9000 guidelines.

In addition, with the swiveling incident light image processing software, you can inspect, measure and document axial and radial geometries of tools — very easily in a single click without expert-level knowledge. You profit directly from at least a 25% productivity increase with your CNC grinding machines simply by measuring your tools before regrinding.