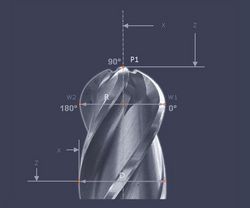

Swiveling multisensor optic carrier »orthoScan«

Easy-to-use measuring of complex tools

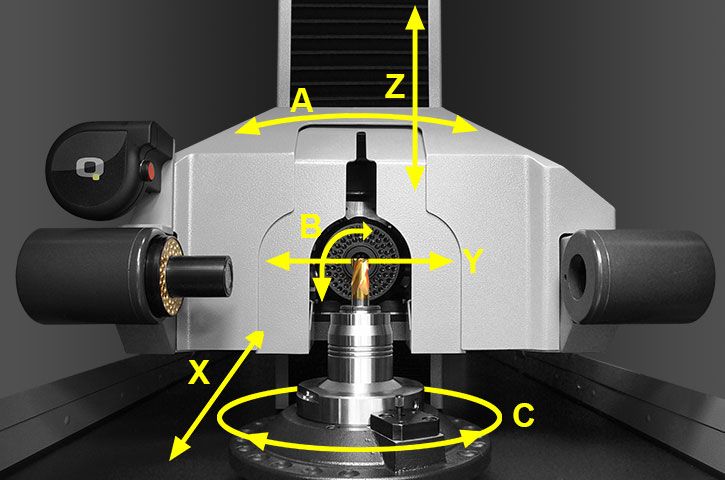

The machine has six CNC-controlled axes

Storage board

Optional manual intervention in the incident light controls

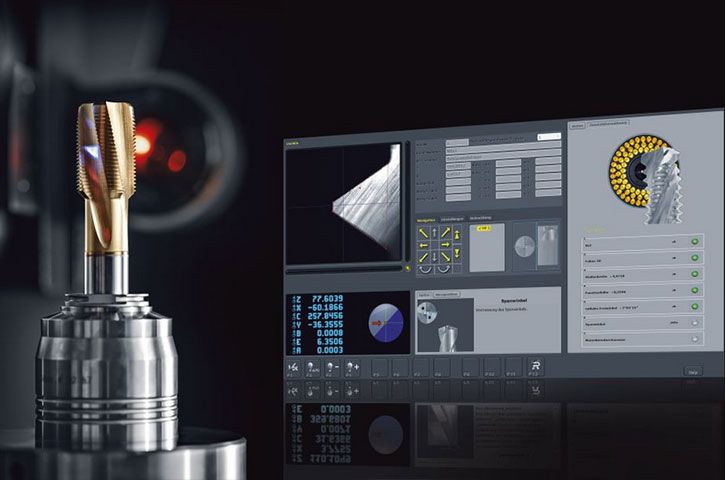

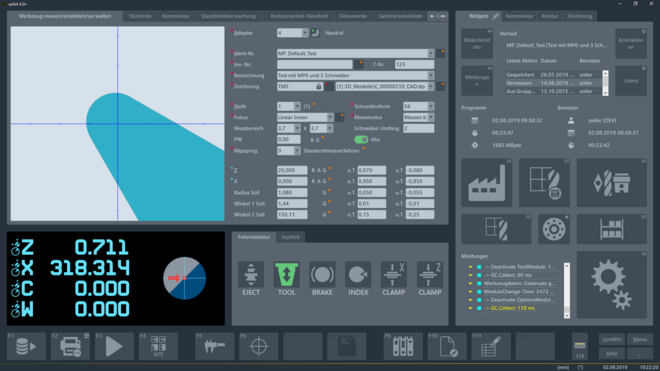

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Max. tool length | Max. tool Ø (with / without swivel mechanism) | Max.snap gauge Ø | Number of axes | Weight | |

| »threadCheck« | 600 mm (23.6 inch | 260 mm (10.24 inch) / – | 100 mm (3.94 inch) | 6 | 820 kg (1 808 lbs) |

Conical Reamers in Snap Gauge Method

Measuring program for the measurement of tapered reamers with the snap gauge method.

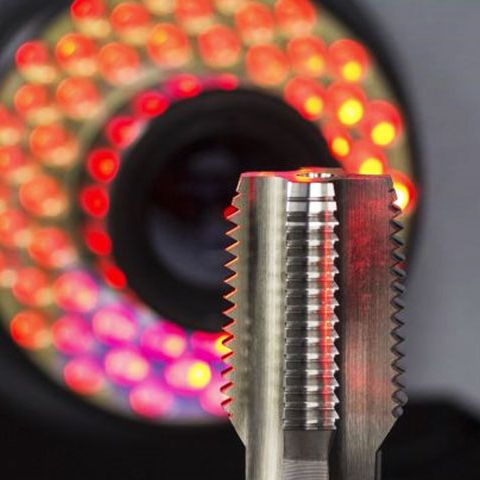

»threadCheck« is the ZOLLER high-end universal measuring machine for distortion-free and precise measuring of cutting tools, including special tooth-edge geometries.

Six CNC-controlled axes and the fully automatic, swiveling multisensor optic carrier »orthoScan« allow complex measurements of threaded tool geometries, threaded drills, milling cutters, molds and many other cutting tools Each highly complex measuring procedures are executed fully automatically: from quick inspection of individual parameters to the complete measuring of complex multi-stage tools. Precise and seamless inspection reports give you and your customers maximum security as well.