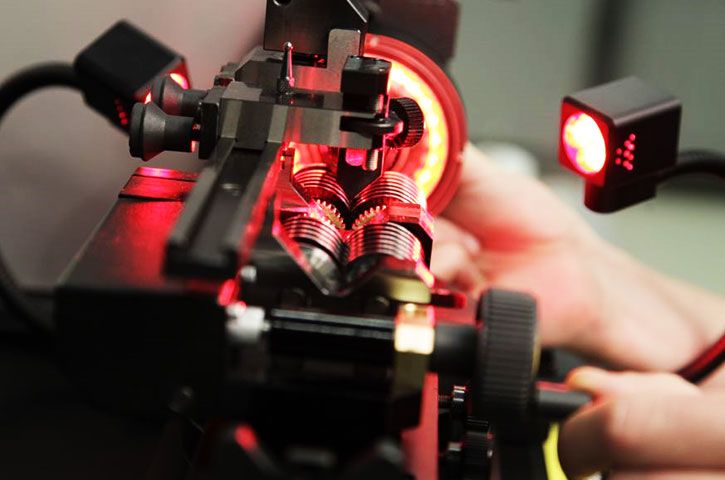

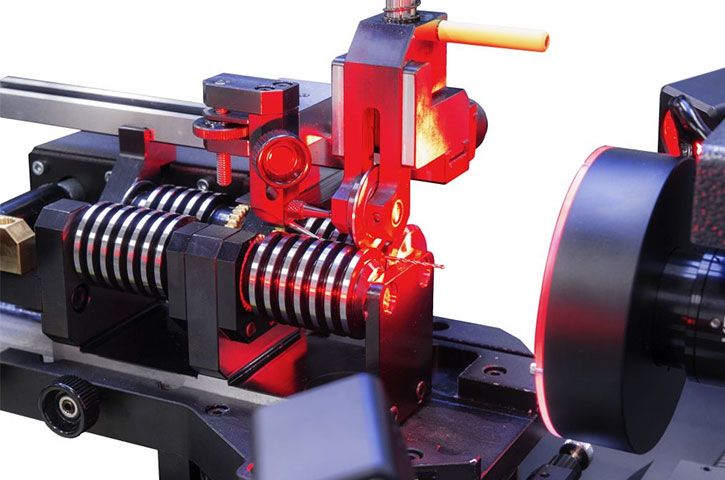

Microscope camera system with 12-times resolution and a focus of 0.5 mm to 6 mm.

Holder for clamping shank tools with a diameter of 2 mm to 32 mm.

Simply and quickly to precise results in the shop floor environment

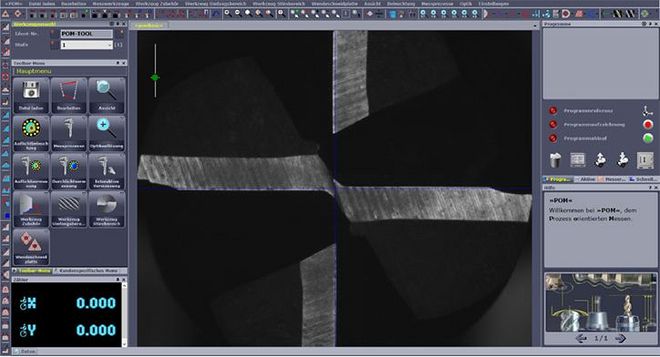

Image Processing Software for Inspection Machines of the »pom« Series

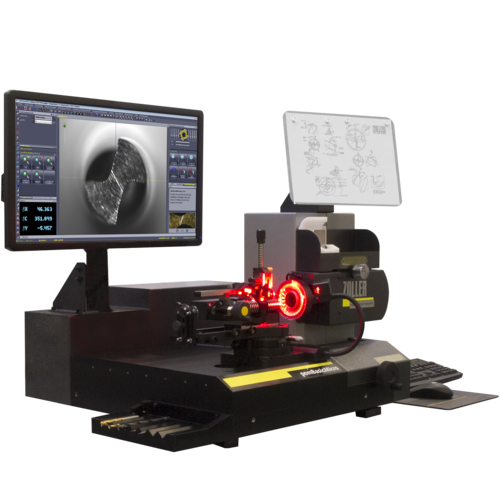

»pomSoft«| Travel range X axis | Travel range Y axis | Travel range Z axis | Measuring and clamping shaft Ø | Color camera »pomColorCam« | |

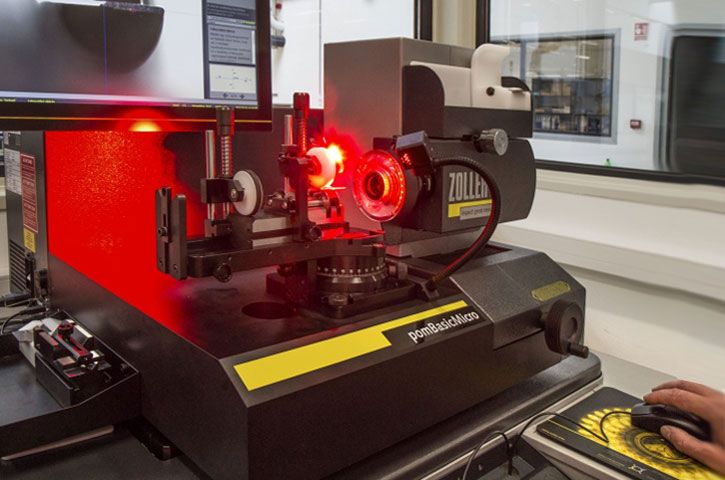

| »pomBasicMicro« | 180 mm (7.1 inch) | 55 mm (2.2 inch) | ± 50 mm (2 inch) | 0,5 mm - 50 mm (0.02 inch - 2 inch) | 12-times zoom macro-lens, Working distance 50 mm |

Vertical and Horizontal Dimension, Angle, Projection

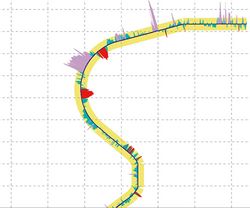

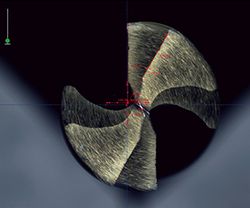

Measuring program for the measurement of reamers for valve seat machining.

Theoretical Tip

Measuring program for the determination of the theoretical tip at tapered cutting tools over several measuring points.

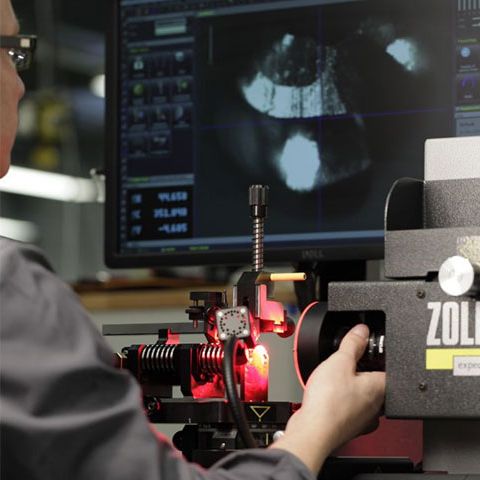

The ZOLLER »pomBasicMirco« is the compact and in-process inspection solution for inspecting and measuring micro-tools. With the special video-micro-system monochrome camera, tools of the smallest sizes can be inspected.

The intuitively operable, individually adjustable »pomSoft« image processing software offers numerous measuring and analysis algorithms, primarily for measuring angles, distances, wear and tear, cutting qualities and grinding patterns. Thanks to its compact and universal design, »pomBasicMicro« can be used in the measuring laboratory, incoming goods inspection or directly in your manufacturing process.