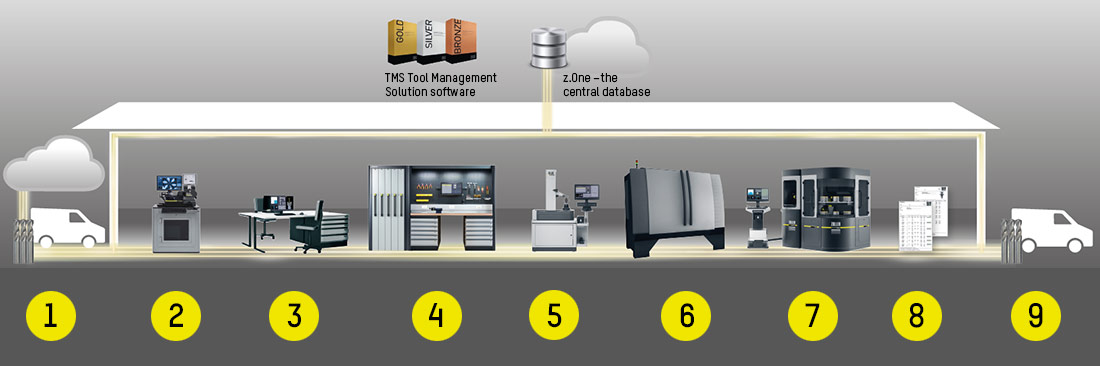

With Measuring Technology 4.0 Solutions from ZOLLER, you are ready for the networked future — the Smart Factory. Whether incoming tool inspection, manufacturing or final inspection: ZOLLER offers the perfect solution for checking and measuring tools, for tool storage, and for automation concepts — all networked with the z.One central tool database.

With the delivery of the tools, tool data is included, either in DIN or ISO format. All data for tool organization are managed via the z.One tool database.

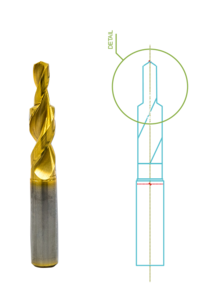

»pomBasic« is the compact solution for universal tool inspection. Actual data are recorded and wear dimensions for tool regrinding are determined. Data is transferred automatically using the »reGrind« software module.

to »pomBasic«

»caz« stands for computer-aided ZOLLER and is a virtual measuring machine. With this software solution you can generate and simulate the measuring processes on a external workstation.

Smart Cabinets store grinding wheels, components and accesories not only in a safe and clear manner, but they also enable an automatic stock control. The graphical display of the storage location facilitates it to find your work materials.

to Smart Cabinets

With »smile« you can measure all relevant geometries of grinding wheels and tools. With »pilot« measuring software you can handle many things with just a click of the mouse. For example completing the measuring processes generated in »caz«.

to »smile« Measuring Machine

The open data interface, GDX (Grinding Data Exchange), ensures the direct data exchange between CAD/CAM system, ZOLLER measuring machine (for example, the »genius«), and grinding machine. Measuring processes are generated automatically and completed securely.

»roboSet 2« — in connection with the »genius« universal measuring machine — is the automation solution for the final inspection of finished tools. Every tool is checked 100% before delivery.

to the »roboSet 2« Automation Solution

Representing work procedures in tool management is done using the digital twin of every single tool. This twin includes geometries and production data, which are available at any time.

Measurement values are available in reports and can be completed including other parameters. All measurement data and tool data are available in the z.One database.

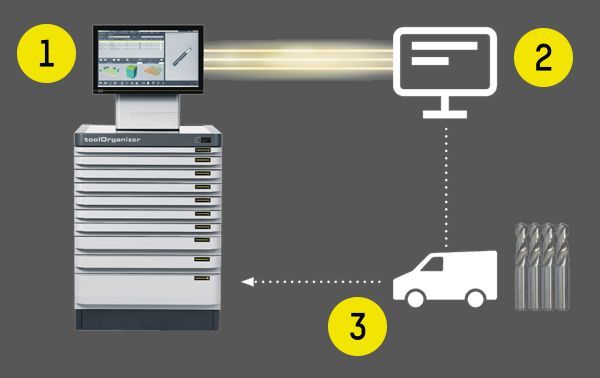

(1) You equip your customers with Smart Cabinets including tool management software from ZOLLER.

(2) Your customer removes the tools from the cabinet and is informed as soon as a minimum stock level is reached..

(3) You deliver the tools as needed. Your customer only pays for the tools he removes.