Precise

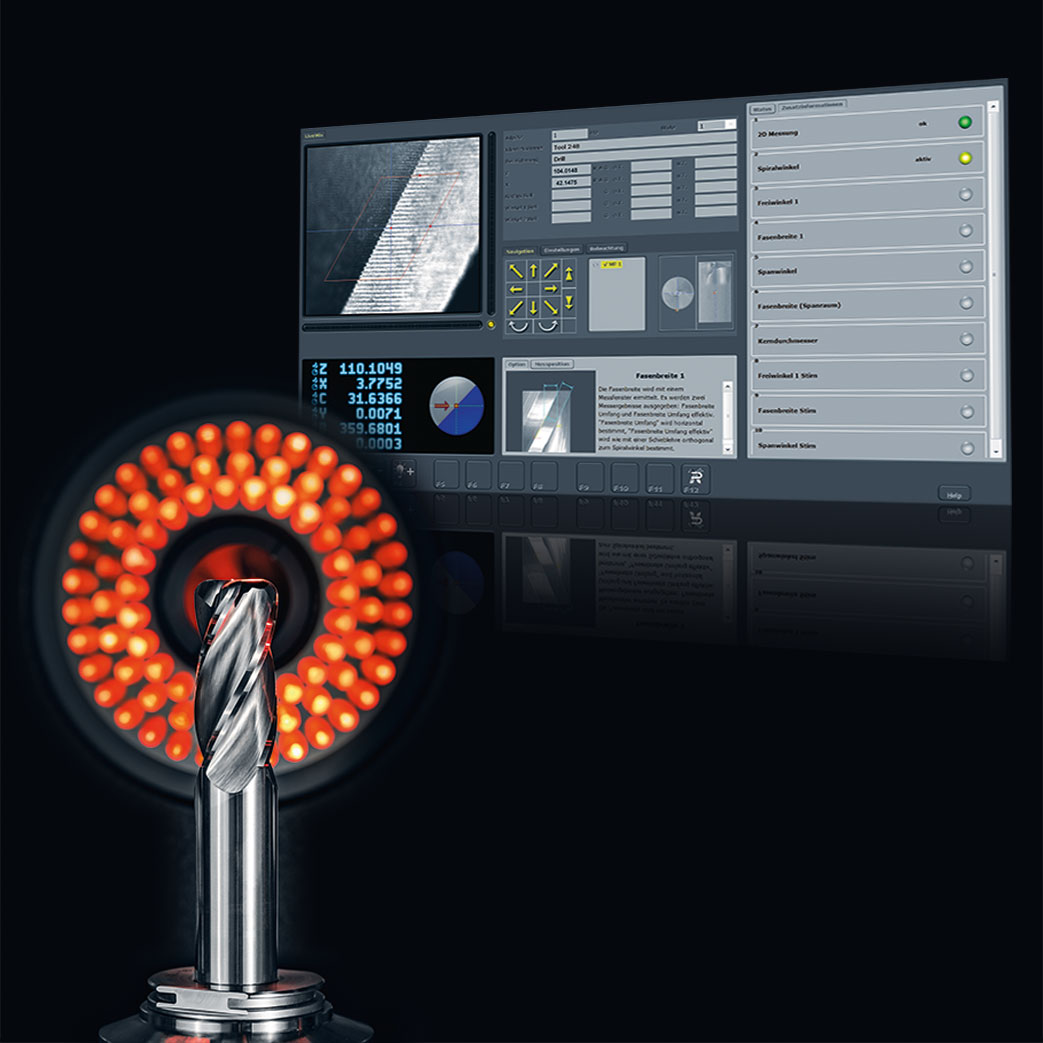

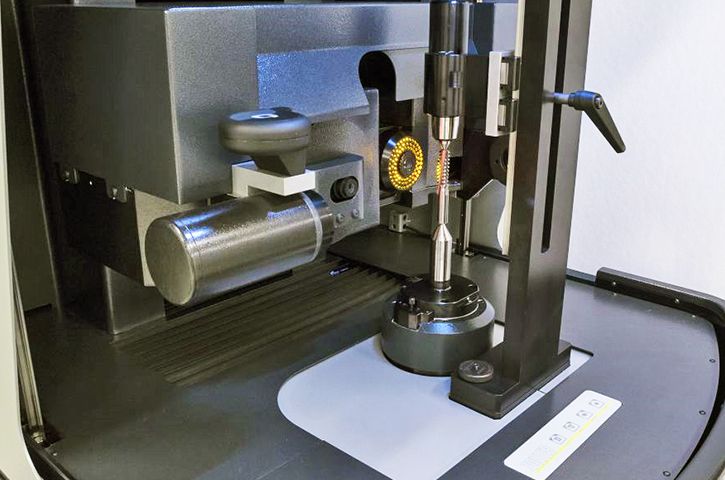

CNC-controlled multisensor measuring system, automatic level control and low-vibration base

Flexible

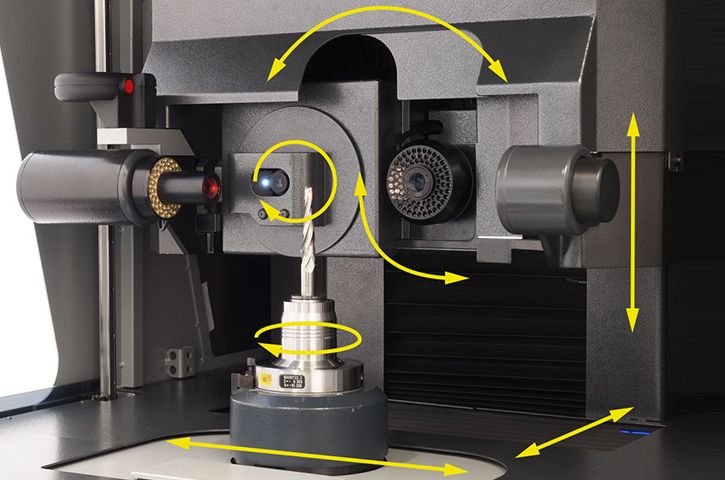

As a result of the transmitted and incident light camera, multi-LED lighting and SKP sensor - controllable with up to seven CNC axes

Safe

Simple operation and ergonomic, space-saving design for safe processes and high levels of working comfort

User-independent

Extremely easy operation, without expert-level skills required

Profitable

Allows even highly complex measurements to fully automatically and quickly - including inspection reports

Something for everything: Measuring of precision tools and cutting edge preparation

Extensive software functions - self-explanatory user interface

Optional tailstock center

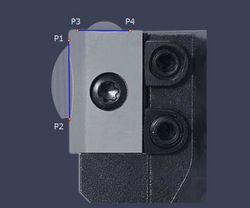

Optic carrier with transmitted light and incident light camera, optic carrier-CNC swivel, micro or Skp-sensor and optional measuring sensor

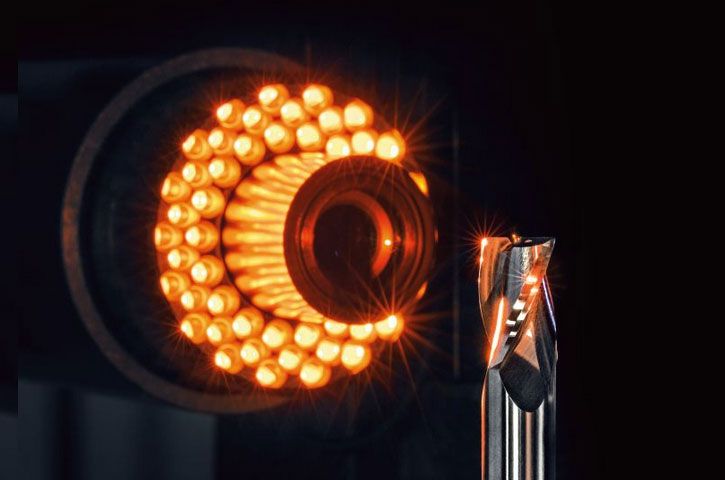

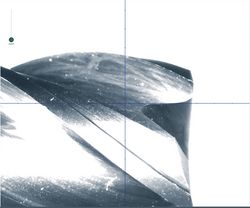

Fully automatic measuring of the cutting edge preparation

Transmitted light camera with cutting edge inspection

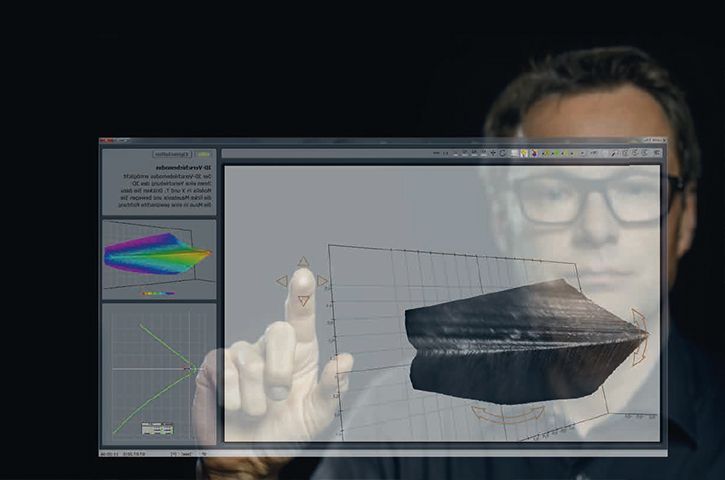

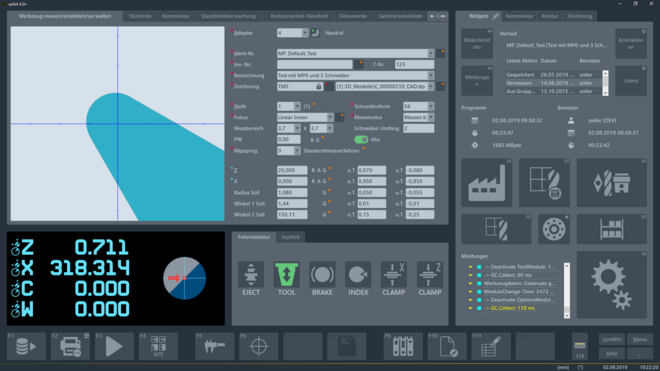

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«

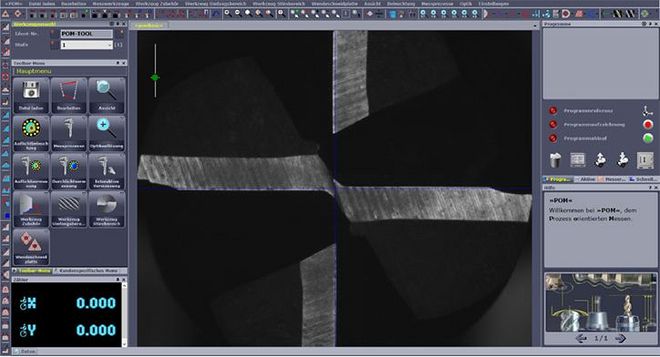

Image Processing Software for Inspection Machines of the »pom« Series

»pomSoft«| Max. tool length | Max. tool Ø (with / without swivel mechanism) | Max.snap gauge Ø | Number of axes | Weight | |

| »titan« | 600 mm | 100 mm / 100 mm | 75 mm | 6-7 | 1400 kg |

Vertical and Horizontal Dimensions, Radius, and Angle of Standard Cutting Tools

Measuring program for the simple measurement of vertical and horizontal dimensions, radius and angle of standard cutting tools.

Single Cutting Edge Reamer - External Processing

Measuring program for the measurement of any parameters at the outer edge of single cutting edge reamers.

Vertical and Horizontal Dimension, Angle, Projection

Measuring program for the measurement of reamers for valve seat machining.

Unrivaled flexibility. Absolutely precision. Simply genius. With »titan«, the new, high-end universal genius, it is possible to complete fully-automated measurement processes, including cutting edge preparation, with a single system.

Seven CNC-controlled axes measure any type of machining tool with high precision and full automation — from exterior contour measurements to operator-independent complete control, including consistent documentation and logging. The fully automatic positioning of the sensors, the high repeatability and the ease of use for even highly complex measuring processes are state-of-the art in in measuring and inspection technology! The operability of the measuring machine can be learned quickly, even for highly complex tasks. This measuring technology solution from ZOLLER brings clear efficiency and quality advantages to you in your manufacturing processes.