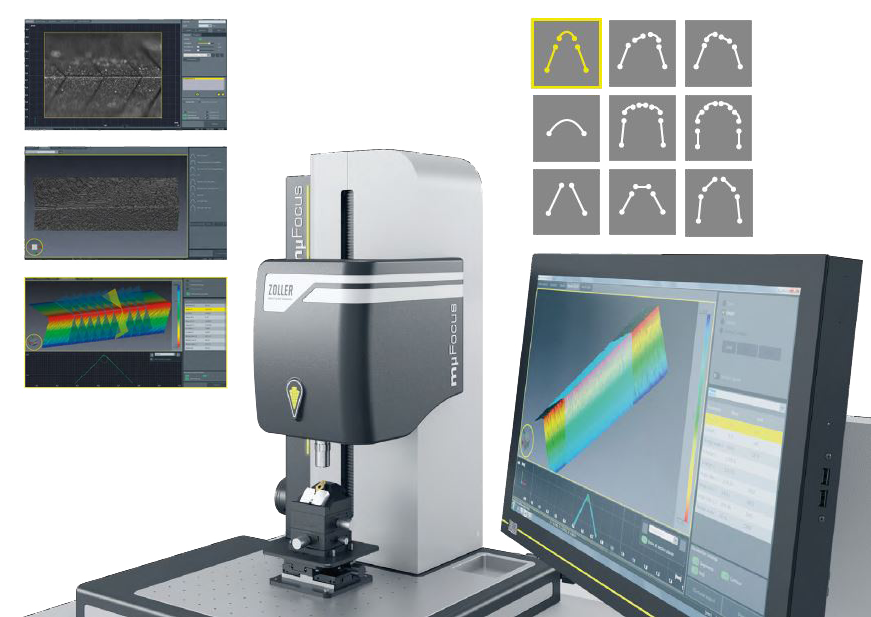

2 in 1: digitize and measure cutting edge rounding and surfaces thanks to confocal microscope

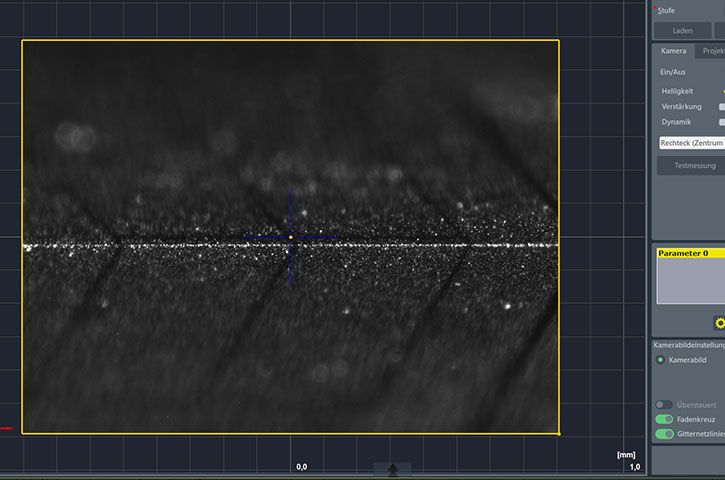

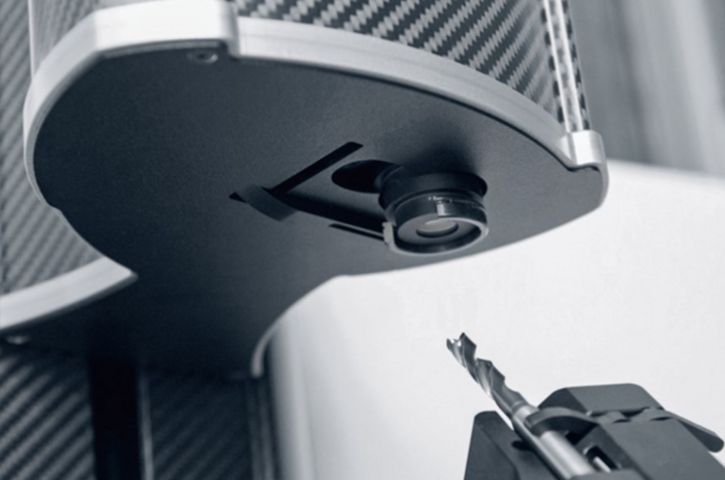

Brilliant: the cutting display including intelligent illumination

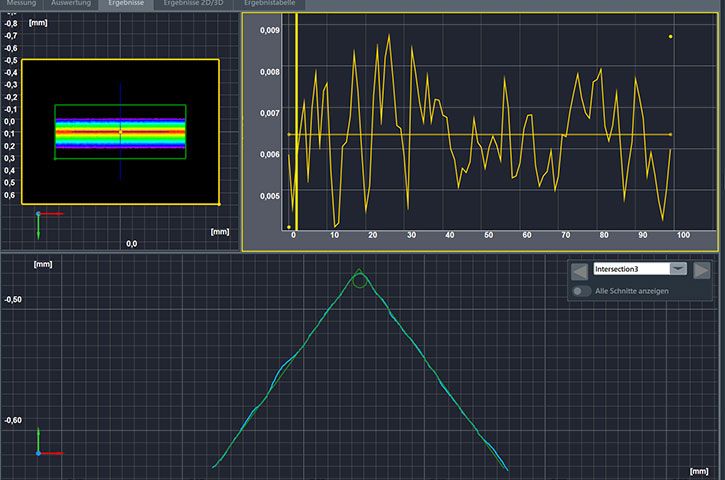

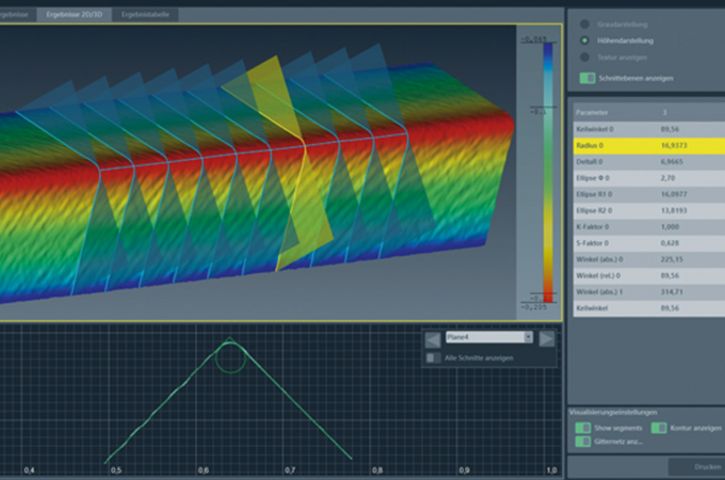

Clearly arranged: all evaluations and diagrams at a glance

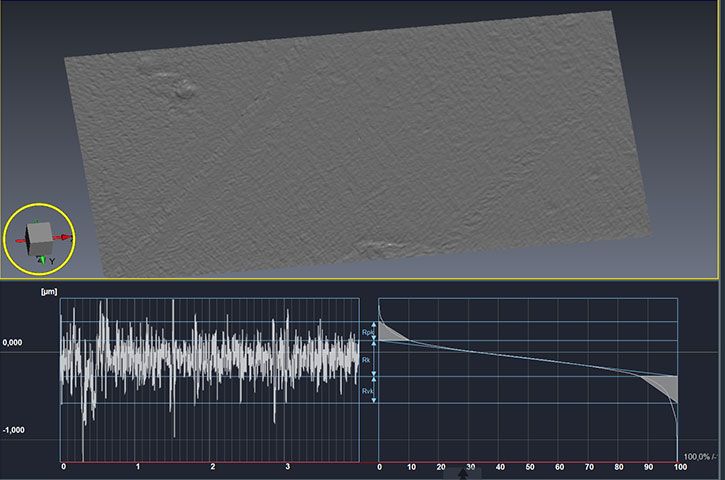

DIN-compliant: standard-compliant evaluation of surfaces and corresponding diagrams

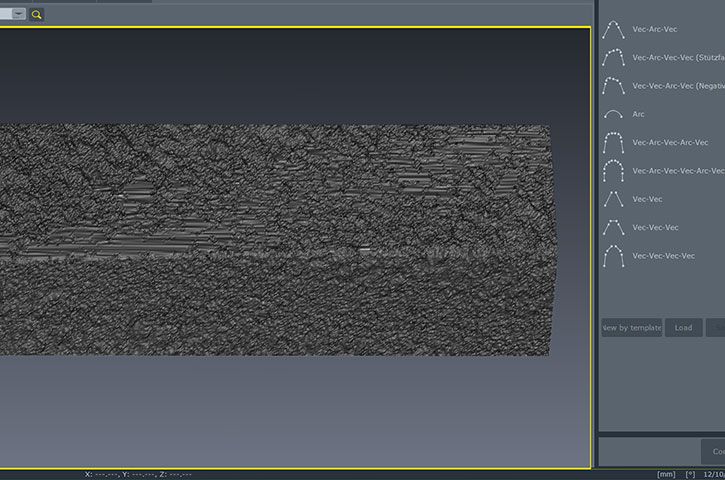

Flexible: »pilot« provides evaluations for all cutting edge shapes

User-friendly: the »pilot« software guides you safely through the measurement process

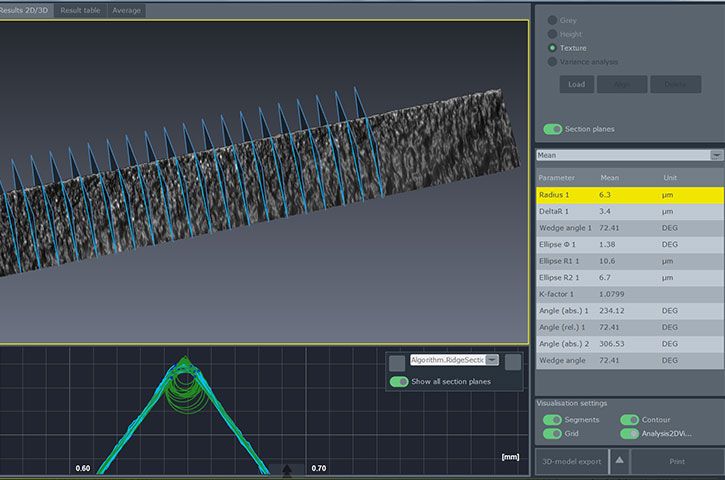

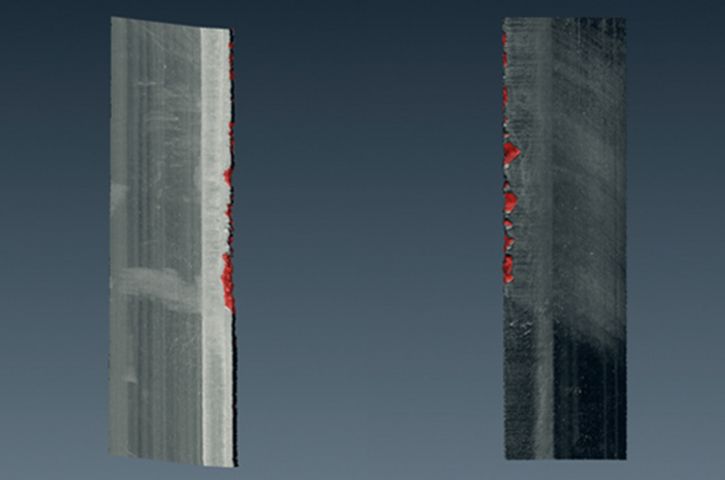

Measure rounding, roughness, wear and chipping

Measure rounding, roughness, wear and chipping

Measure rounding, roughness, wear and chipping

Measure rounding, roughness, wear and chipping

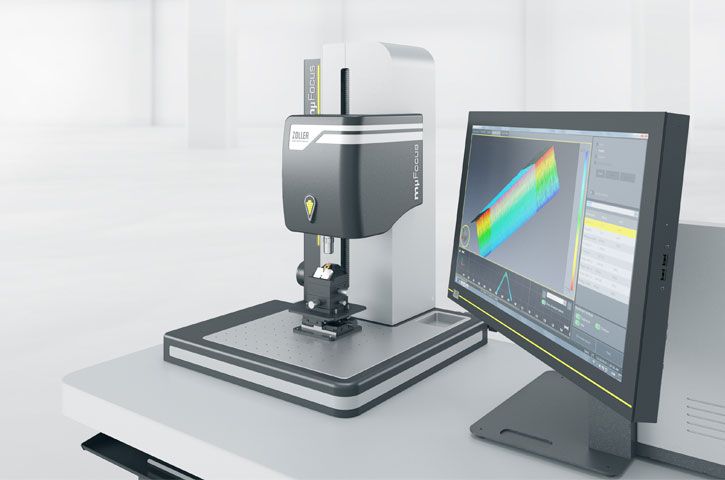

The Most Modern Measuring Software

»pilot« machine software offers comprehensive convenience. The selection and input fields are easy to understand, all functions support efficient work, and the software offers multiple options to prepare measured values and display them in a clear way.

Guides You to the Finest Structures

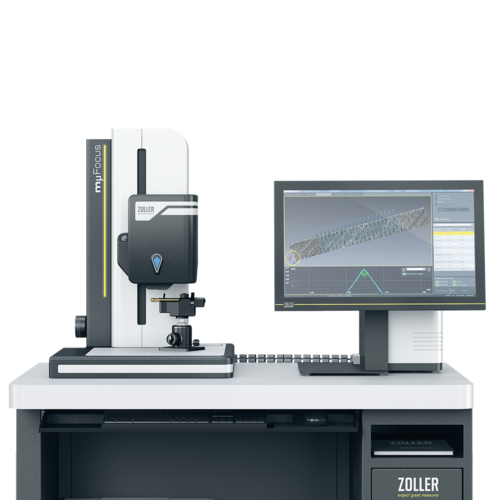

ZOLLER »mµFocus« systematically approaches microstructures. Clear processes and supporting tools provide detailed insight of cutting tool edges and surfaces. You can detect wear quickly, create a 3D model with just one click, and easily measure cutting edge preparation and roughness. »mµFocus« takes multiple individual images to record comprehensive raw data, then uses it to calculate a 3D model of the cutting edge. Then you can complete a standardized analysis of the measuring results and prepare them graphically using »pilot«.

| »mμFocus« Features | Symbol | Z axis | AA* | Measuring principle | Smallest measurable radius | Numerical aperture |

| »zep« Sensor to measure cutting edge geometry | blue | 300 mm | 30 mm | Strip projection | 3 µm | - |

| »zep-R« Sensor for measuring 3D cutting edge geometry and surface roughness | yellow | 300 mm | 20 mm | Confocal microscope | 3 µm** | 0,42 |

You want to produce the perfect cutting edge – one that ensures a long tool life, minimal wear, optimal chip formation, and precision workpiece processing, thereby significantly lowering costs for production.

Achieve your goals with high-precision tool geometry and optimal surface textures customized to your specific application. If you want to ensure exact, standardized quality in your tool development, then the ZOLLER »mμFocus« inspection machine is the right choice for your needs.

»mµFocus« uses non-contact measurement procedures to determine the surface roughness and cutting edge prepara-tion of your tool, down to the µm. Use the ZOLLER »mμFocus« to create fully optimized tools.

“For me, to assembly a »mµFocus« is something special every single time. The machine combines two different characteristics you would not necessarily expect to go together: Although it is extremely heavy with a massive weight of 200 kilograms, it offers highly precise measuring technology that measures exactly, down to the µm. I install top-quality sensors and many other elements using modern technolo- gy into »mµFocus« machines. I am very proud that installing the »mµFocus« is one of my duties.

I can promise you one thing: The »mµFocus« is a seriously high-tech machine you can use to easily measure cutting edges and surfaces with outstanding precision.” says Markus Müllner, Measuring Technology Fitter at ZOLLER.