Z.magazine 2016

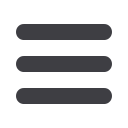

Major Diameter

Minor Diameter

Core

Diameter

Major Diameter

DATA AT A GLANCE

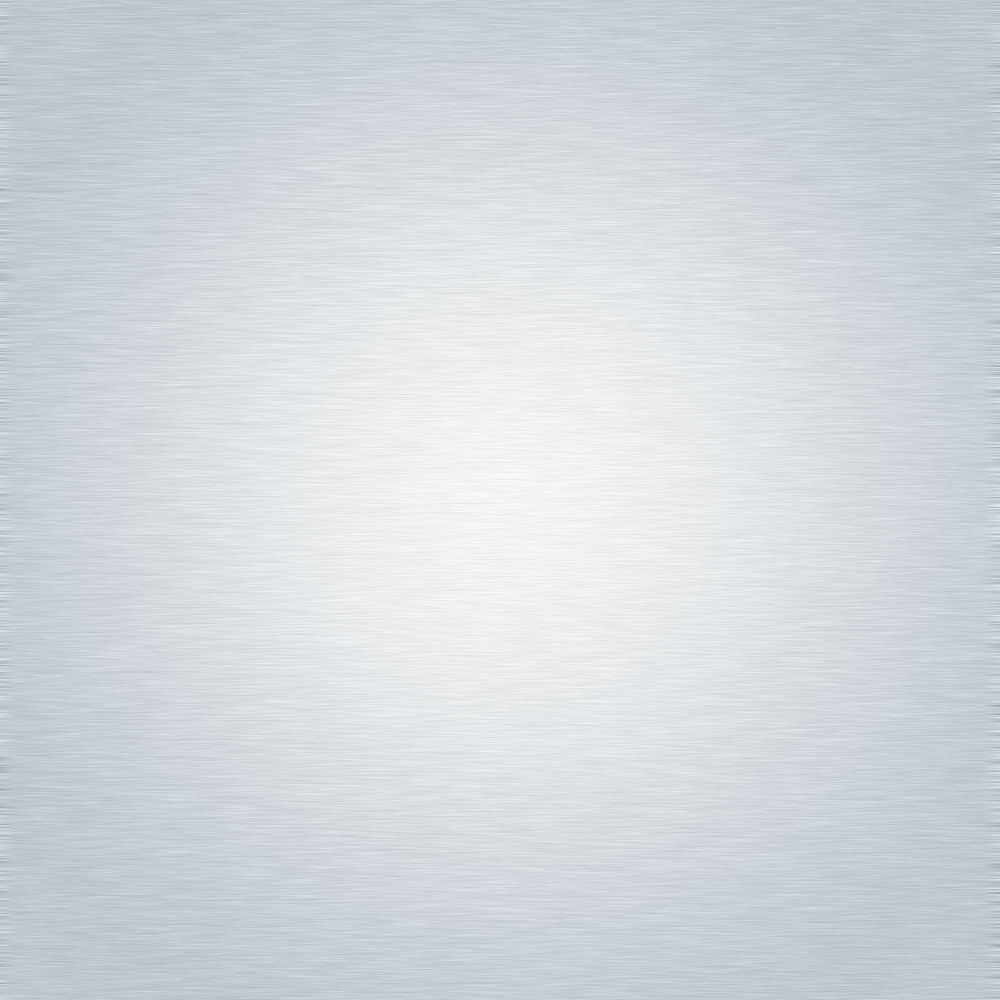

PROCESSES UNDER CONTROL

»threadCheck« also transmits data

to other areas of the production

process via the ZOLLER database

with interfaces to all commonly

used third-party systems. This means

that you always retain an overview of

current actual data for individual tools,

and these can then be recombined at

various production stages. This is espe-

cially important with threaded bores.

This just-in-time data is important be-

cause it is usually executed at the end

of a sequence of manufacturing oper-

ations, which can result in very costly

mistakes. Machine downtime as a result

of input errors is eliminated.

»threadCheck« can be supplemented

with a tool management system for re-

cording and managing grinding wheels

and grinding wheel packages. Detailed

information about the grinding wheel

packages can be set up, and tools can

be assembled virtually from the comfort

of your office via the TMS connection.

All in all, with this universal measuring

machine for metal cutting and tapping

tools, ZOLLER has once again created

a solution for new developments in the

manufacturing sector. And at precisely

the right time. As always, the system is

configured in a way that enables it to be

adapted to suit additional requirements

for efficient operations both now and in

the future.

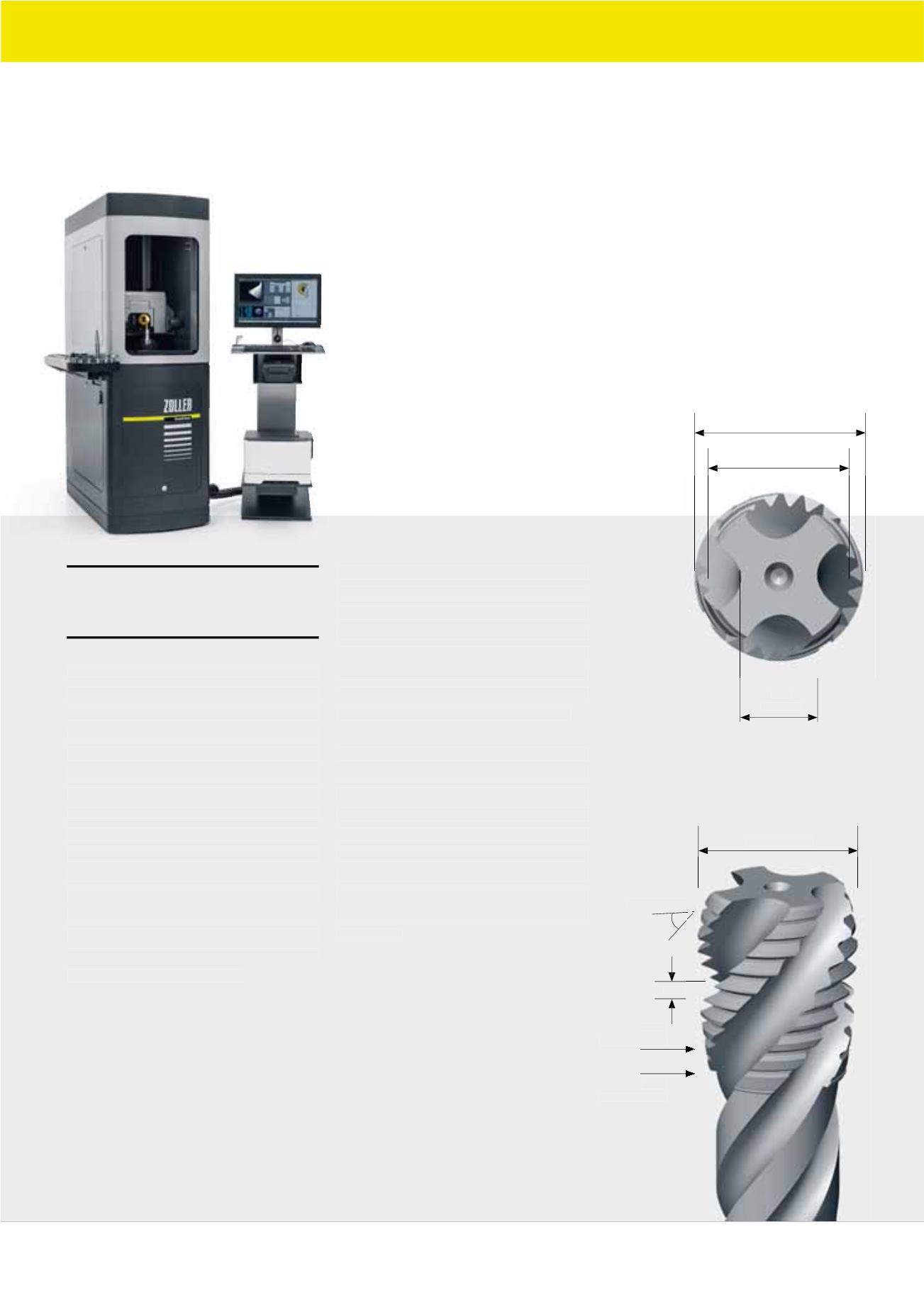

Pitch

Relief

Flank Diameter

Chamfer Angle

Relief

Major Diameter

TREND

10