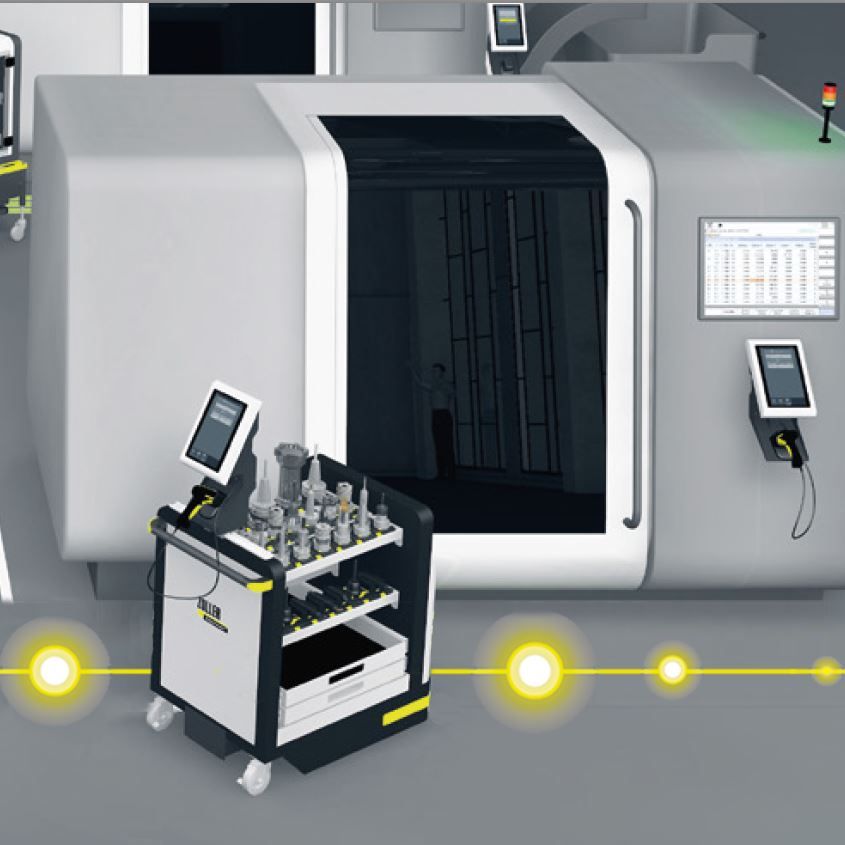

Wrong data entry can be enough to steer your CNC machine into a crash. With ZOLLER's »zidCode« and »zidCode 4.0« solutions, you can transmit the measurement and setting data as well as the tool ID digitally and error-free to almost any common CNC machine and thus avoid the machine crash.

By scanning the 2D code on the tool, all data is read in correctly at the CNC machine.

Integrate »zidCode« into your production simply by plug-and-play – without complicated programming and without hours of machine downtime.

»zidCode« quickly gets your production ready to use digital tool data conveniently in your processes. After just a short time, your data will flow to the CNC machine without errors and in a control-ready manner.

This is how the ZOLLER Identification Code »zidCode« increases your manufacturing efficiency:

With »zidCode« you achieve time savings of up to 45%. That's the best profit you can make!

For manufacturing operations with their own network. The »zidCode 4.0« (as a communication platform), which opens even more options for your tool data.

The »zidCode 4.0« communication platform not only ensures correct and secure data transfer of the tool geometry data, but also speeds up the tooling system in the various machines enormously. Once you have completely created the tool data, you can also transfer all machine-relevant tool data to any machine control via scanning.

Uniquely identify tools, securely transfer tool data and plan tool use even more efficiently by communicating via your network: you get all this with »zidCode« – the efficient solution for efficient tool handling before and after setting up your machine. The result: with »zidCode 4.0« you increase your process reliability and thus also your productivity. At the same time, you enter digitalised manufacturing without high investment costs or complex retrofitting and are thus well equipped for a successful future.

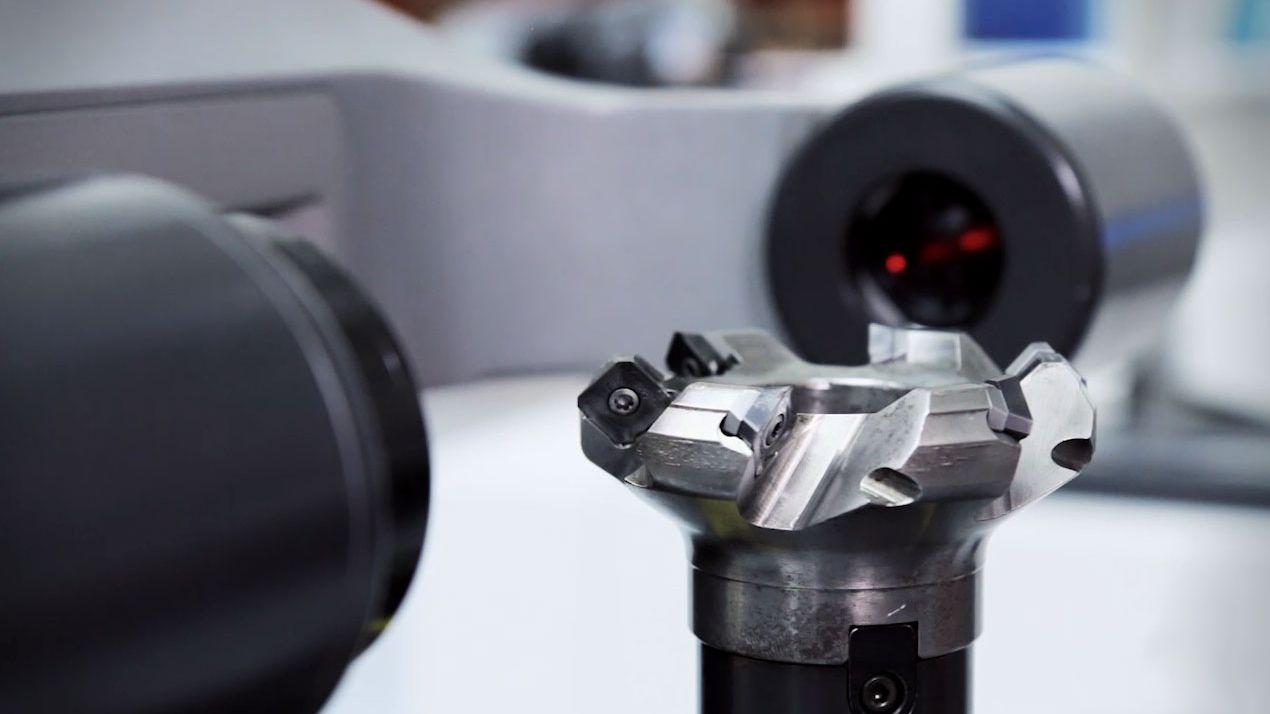

You remove the tool holder, which is provided with a 2D code, mount the cutting tool and you're ready to go. By simply scanning the code, the data is immediately recorded and inventoried in the »pilot« software and is available for further processing.

After the 2D code of the complete tool has been scanned and the tool has been inserted, everything else takes place quasi automatically, because: Thanks to this networked solution, the ZOLLER setting and measuring device knows exactly which measuring programme is intended for this particular tool. After the measurement, the data is stored in the software or the central tool database z.One.

Scan tools at the »zidCode« unit and your machine automatically receives the corresponding tool data from the network. Thanks to the post-processors and the data prepared in accordance with the control system, your machine can start immediately and produce only correct components.

The ZOLLER identification code is a new and efficient solution for tool identification and data transfer developed specifically for small to mid-sized businesses. »zidCode« does not need a network connection, but instead transmits data for complete tools without complication using a QR code.

You can save 45% of the time spent manually entering actual tool data into the machine controls. Input errors are also avoided entirely – time-consuming reworking is eliminated, and process security is increased.

Presetting and measuring tools on the ZOLLER presetting and measuring machine

Print actual tool data on label including QR code and attach to tool

Scan QR code label using »zidCode« at the CNC machine, the actual tool data is automatically entered into the corresponding data fields of the CNC machine control.

No more typos, no machine crashes, optimum usability with lathe machines - all these advantages and more in the video!

New, inexpensive and economical: »zidCode«