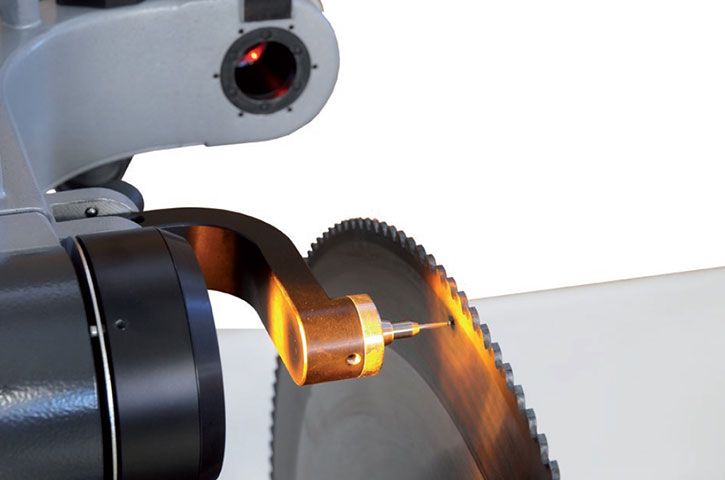

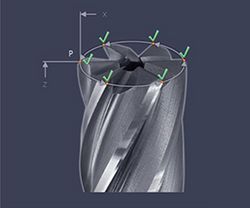

Measuring sensor for runout compensation on the master blade, from D300 mm

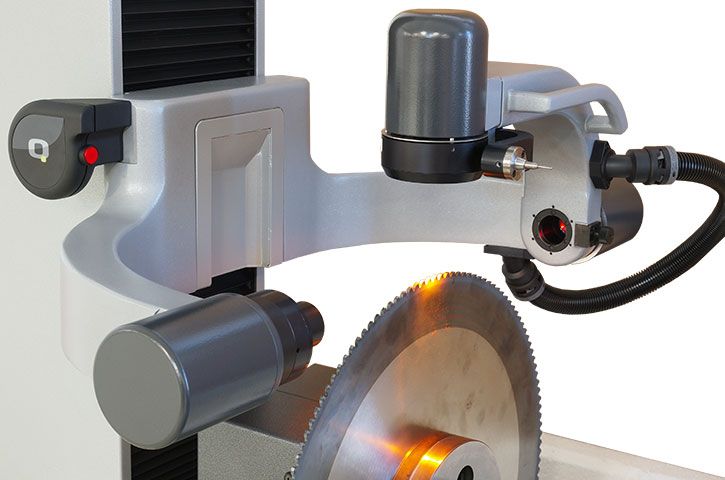

Precision camera swivel for axial and radial measuring in incident light

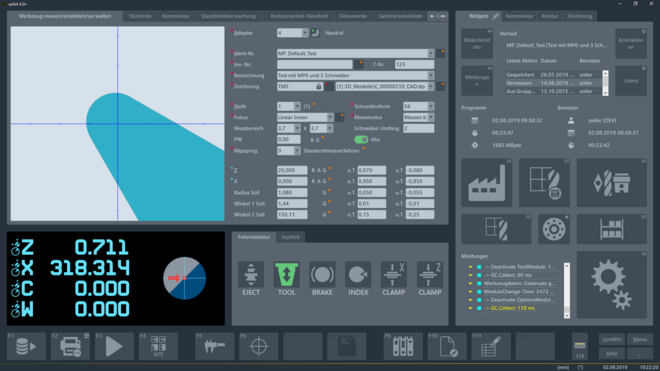

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Travel range Z axis | Travel range X axis | Measurable Ø in transmitted light | Measurable Ø in incident light | Max. tool width in Z direction | Max. tool weight | Measuring sensor | |

| »sawCheck« | 450 mm | 200 mm | 300-800 mm | +90°= 300-800 mm; 0° and -90°= 200-800 mm | 30 mm | 50 kg | Axial runout measurement |

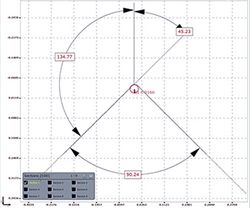

Conical Reamers

Measuring program for the measurement of tapered reamers without support bar .

Vertical and Horizontal Dimension, Angle, Projection

Measuring program for the measurement of reamers for valve seat machining.

Theoretical Tip

Measuring program for the determination of the theoretical tip at tapered cutting tools over several measuring points.

There are ever-increasing requirements in manufacturing in regards to accuracy and efficiency, especially when it comes to the regrinding of precision saws. With the ZOLLER »sawCheck«, you possess a user-independent, fully automatic and touchless solution for measuring sawblades, tooth by tooth.

»sawCheck« is efficient and precise, and includes the ability to record measurement results seamlessly. When inspecting teeth, parameters such as tooth shape, division, concentricity, radial runout of the cutting edge and more can be inspected touchless and quickly in transmitted light. Meanwhile, rake angle, clearance angle, tooth thickness, center offset and wear and tear, which can be measured in incident light, both radially and axially. As an option, the axial runout of the master blade can be determined with a measuring sensor. This information is then taken into account when measuring other parameters. ZOLLER provides the solution for a safe and complete check of precision saws — for both manufacturers and for grinding shops.