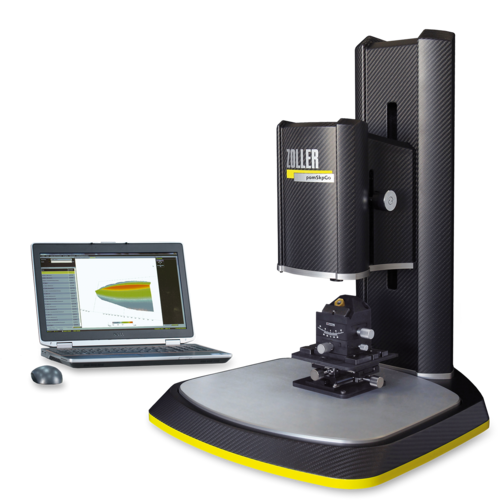

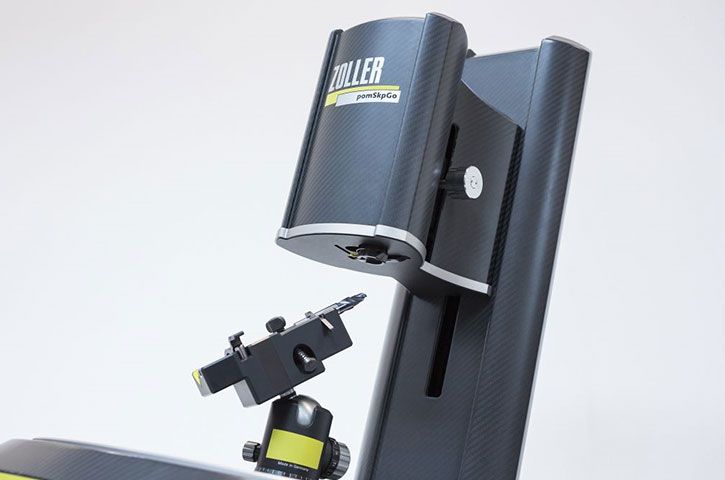

The design of the ZOLLER »pomSkpGo« made from carbon is sufficiently rigid for high-precision measuring and sufficiently light for mobile use.

Ideal for measuring indexable inserts, drills and milling cutters.

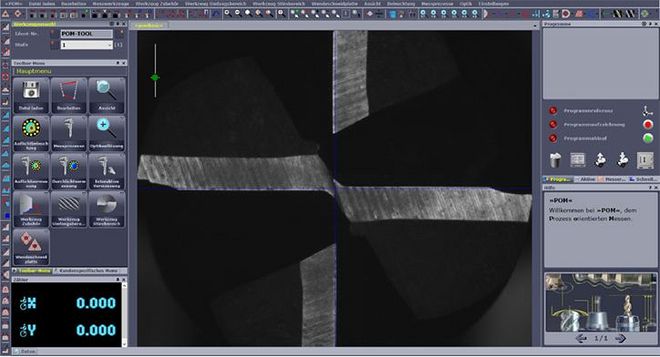

Image Processing Software for Inspection Machines of the »pom« Series

»pomSoft«| Manual quick adjustment | Manual fine adjustment | Measuring height | Smallest measurable radius with »skpPremium« measuring sensor | |

| »pomSkpGo« | 200 mm | ± 50 mm | 0 - 300 mm | 0.003 mm |

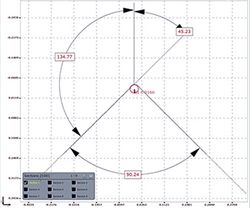

Theoretical Tip

Measuring program for the determination of the theoretical tip at tapered cutting tools over several measuring points.

This ZOLLER solution for inspecting the cutting edge preparation of milling and drilling tools, as well as turntables, scores 100% for shop floor use, has unrestricted mobility, an intuitive user guidance and precisely traceable results. The »pomSkpGo« is ideal for commissioning and inspection of rounding machines, directly in cutting body manufacturing and at the incoming goods check. The basic carbon construction allows for mobile use and facilitates a high level of accuracy thanks to its rigid design. The machine can be set up and ready for use in just 5 minutes.