New Video: Simple Solutions for Data

Transmission with »zidCode«

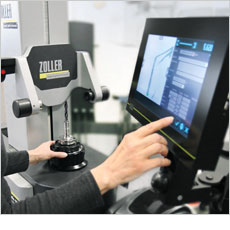

The efficient solution for

tool identification and data transmission! Watch how simple

and secure data transmission is — even without a network

connection — using »zidCode« (ZOLLER identification code). The

process is very simple because tools are measured on the

ZOLLER presetter and measuring machine, then all data is

encrypted into a QR code and printed on a label. Read

the QR code with the reader to automatically transfer it

to the controls of the CNC machine — manual data input and

typos are eliminated.

| ||||||||||||

|

| ||||||||||||||||

| ||||||||||||||||

| ||||||||||||||||

| ||||||||||||||||

| ||||||||||||||||

| IMPRINT: Responsible for content (according to §6 MDStV): E. Zoller GmbH & Co. KG, Einstell- und Messgeräte, Registration Court Stuttgart HRA 202201 General Partner: E. Zoller GmbH, Stuttgart, Registration Court Stuttgart HRB 203149, VAT Registration Number: DE 146132622 General Manager: Christoph Zoller, Alexander Zoller, Eberhard Zoller Postal and delivery address: Gottlieb-Daimler-Straße 19, D-74385 Pleidelsheim. ZOLLER India Pvt. Ltd. | Presetter and Measuring Machines Plot No. RM 104, Sanjeevani Complex, Near KSB Chawk, MIDC, Shahu Nagar Chinchwad, Pune, 411019, India info@zoller-in.com • www.zoller-in.com If you do not want to receive any further information from us, please unsubscribe here. | ||||||||||||||||