|

|

|

|

|

|

|

"Intelligence in production" – this was the motto of this year's EMO. ZOLLER presented over twenty innovations on this subject, two of which we would like to showcase in this newsletter:  the future of modern tool data management the future of modern tool data management and  new products from the »pom«-series new products from the »pom«-series for tool inspection.

"State-of-the-art" not only applies to our novelties at the trade fair, but also to proven ZOLLER technology. With over 6,500 units in operation since 1997, the »venturion« class of tool presetter and measuring machines provides intelligent solutions for the daily challenges in the production environment. For the vacuum valve manufacturer VAT it represents a  strong partner in zero defect production. strong partner in zero defect production.

On behalf of the ZOLLER team

|

|

|

|

|

|

|

|

|

| The future of modern tool data management |

|

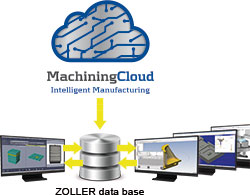

The reproduction of an oversized ZOLLER database on the exhibition stand used neon tubes as symbols to connect the product areas tool presetting and measuring as well as tool measurement technology – the future of modern tool data management in production, with more and more manufacturers of tools providing their data in the "Tool Cloud". Visitors to the stand were able to experience this live. "With this state-of-the-art solution, users can download all tool data required for programming directly into their system. As first partner of the MachiningCloud, ZOLLER is in a position of using these data. For example, 3D models can be created directly from these data, and CAM systems can be provided with complete tool data in 2D and 3D as well as with article characteristics", explains cloud expert Michael Taesch. "A data unit is no longer required, the data are directly available". This makes tedious entering of tool data by hand a thing of the past.

|

|

|

|

| Tool measuring technology: exhibition novelties »pom« series |

|

The machines of the »pom« series for process-oriented measurement provide maximum in-process capabilities. They can also be employed outside the metrology room, directly in production. The »pomBasicMicro« was presented for the first time at the trade fair. This compact tool inspection unit for workshops, directly adjacent to the CNC grinding machine, is now also available with a high-resolution camera for micro tools. The newly developed swivel table allows measurement of tools at freely selected angles. More information on the basic machine »pomBasic«, the compact solution for universal tool inspection, can be found here.

|

|

|

|

| Proven: a strong partner in zero defect production |

|

VAT, an internationally operating Swiss company and market leader in vacuum valves for the semiconductor and vacuum coating industry, has been manufacturing in accordance with the zero defect principle for years. This requires unconditional quality - across the entire value chain. The ZOLLER-»venturion« is the matching measurement solution to support this strategy successfully.

Urs Roduner, Tool Coach and responsible for tool procurement at VAT, underlines the safety and reliability of the ZOLLER machines as major advantages in all fields of application: "No matter which age, nationality or level of education, in fact, no matter who operates the machine: I can rely on the results one hundred percent."

|

|

|

|

| |

|

|

| ZOLLER – Products and Solutions from one single Source |

| |

|

|

|

|

|

|

|

|

IMPRINT:

Responsible for content (according to §6 MDStV):

E. Zoller GmbH & Co. KG, Einstell- und Messgeräte, Registration Court Stuttgart HRA 202201

General Partner: E. Zoller GmbH, Stuttgart, Registration Court Stuttgart HRB 203149

VAT Registration Number: DE 146132622

General Manager: Christoph Zoller, Alexander Zoller, Eberhard Zoller

Postal and delivery address: Gottlieb-Daimler-Straße 19, D-74385 Pleidelsheim.

ZOLLER India Pvt. Ltd. | Presetter and Measuring Machines

Plot No. RM 104, Sanjeevani Complex, Near KSB Chawk, MIDC, Shahu Nagar Chinchwad, Pune, 411019, India

info@zoller-in.com • www.zoller-in.com

If you do not want to receive any further information from us, please unsubscribe here.

|

|